| Quantity: | |

|---|---|

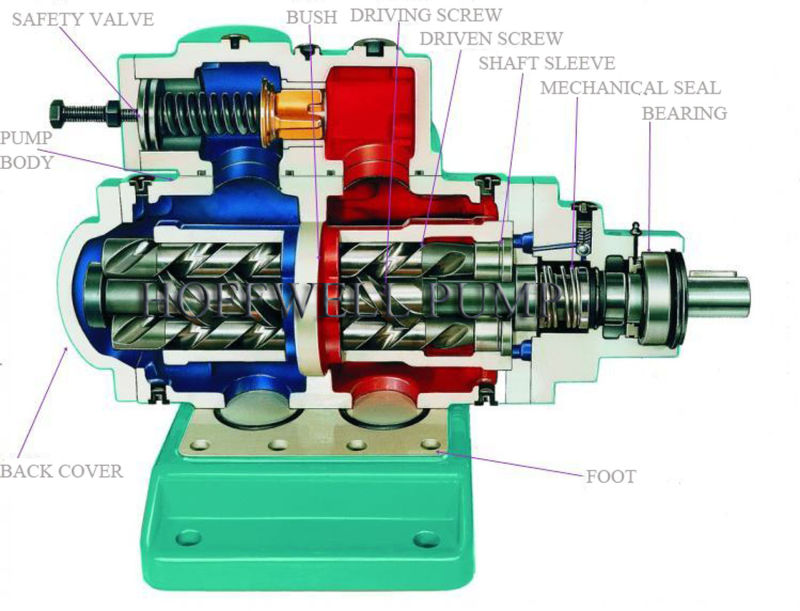

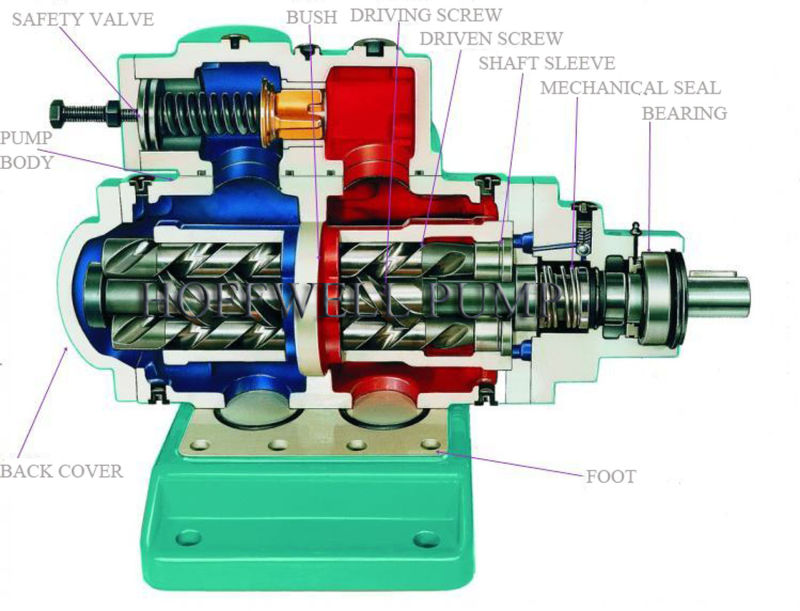

1. Advanced structure and excellent performance: The traditional high-pressure balance technique is changed, and the axial force balance of power and idler rotors at low-pressure is adopted, with even stress distribution, almost no deformation of screw, reliable and stable operation, no impulse, and low noise;

2. Unique design and reliable sealing: The mechanical sealing method is adopted for pump, with the sealing cavity interlinked to the suction; at the same time, the structure is designed to provide sufficient cooling cycle to the sealing, to ensure the sealing effect and no leakage;

3. Optimized improvement and aesthetic appearance: The traditional inlet and outlet positions are changed, so that they are located at both sides of the pump but in a straight line, resulting in a pleasing appearance; meanwhile, the design is innovated and therefore the inlet and outlet could be exchanged on user's site without any change to pipelines;

4. Pump core assembly for convenient maintenance and accessory replacement: The pump is in a simple and compact structure, and the pump core assembly is in assembly construction; therefore, the pump core can be taken out as a whole, which is convenient for maintenance and repair;

5. Pressure relief valve for the protection of pump: The valve equipped on the product can provide transient protection to the pump, to prevent overload, however, it can not be used as the overflow valve for the pipe.

6. Various combinations of inlet and outlet, convenient for piping on site;

7. Various mounting available, to meet different mounting requirements in the working conditions.

| Descriptions of main parameters for pump type | Separator | Descriptions of auxiliary parameters | |||||||||

| Industry code | Series code | Mounting type | Codes for screw parameters | Lubrication type of bearing | Relative position between inlet and outlet | Special requirement | Operating speed | MPa | |||

| Specification code | Spiral direction of power rotor | Inclination angle | |||||||||

| C | SN | H | 660 | R | 46 | W | Z | T1 | / | 2P | 25 |

| 1. Industry code: No code (common use); C (special use on vessels); D (special use in electric power industry); S (special use in petrochemical industry); the "special use" means the product is specially designed and produced for an industry to meet the special requirements of the industry; 2. Mounting type: H (horizontal mounting); F (bracket-type mounting); S (vertical mounting); K (Immersion-type mounting); 3. Specification code: Refer to the performance parameter table for the details; 4. Spiral direction of power rotor: R (common use, with right-handed spiral direction of power rotor); L (left-h | |||||||||||

1. How to get our quotation in time, please answer following questions:

A.What liquid do you transfer? Oil, Water, Food or Corrosive Chemical liquid, with solid particle or not, and so on~

B. What's the flow or capcity (m3/h, L/m)?

C.What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

D. Contact us to get the quotation:

2. OEM: Ok

3. MOQ: 1set

4. Package: Standar export Plywood Case or Styrofoam with Carton

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Term of payment: 100% T/T, Aliexpress, L/C, Westunion

8. Why choose us: more than 20 years experiences manufacturer

Good quality with competitive pirce

ISO2000, CE certificate, CCS certificate

Professional after-sales service

1. Advanced structure and excellent performance: The traditional high-pressure balance technique is changed, and the axial force balance of power and idler rotors at low-pressure is adopted, with even stress distribution, almost no deformation of screw, reliable and stable operation, no impulse, and low noise;

2. Unique design and reliable sealing: The mechanical sealing method is adopted for pump, with the sealing cavity interlinked to the suction; at the same time, the structure is designed to provide sufficient cooling cycle to the sealing, to ensure the sealing effect and no leakage;

3. Optimized improvement and aesthetic appearance: The traditional inlet and outlet positions are changed, so that they are located at both sides of the pump but in a straight line, resulting in a pleasing appearance; meanwhile, the design is innovated and therefore the inlet and outlet could be exchanged on user's site without any change to pipelines;

4. Pump core assembly for convenient maintenance and accessory replacement: The pump is in a simple and compact structure, and the pump core assembly is in assembly construction; therefore, the pump core can be taken out as a whole, which is convenient for maintenance and repair;

5. Pressure relief valve for the protection of pump: The valve equipped on the product can provide transient protection to the pump, to prevent overload, however, it can not be used as the overflow valve for the pipe.

6. Various combinations of inlet and outlet, convenient for piping on site;

7. Various mounting available, to meet different mounting requirements in the working conditions.

| Descriptions of main parameters for pump type | Separator | Descriptions of auxiliary parameters | |||||||||

| Industry code | Series code | Mounting type | Codes for screw parameters | Lubrication type of bearing | Relative position between inlet and outlet | Special requirement | Operating speed | MPa | |||

| Specification code | Spiral direction of power rotor | Inclination angle | |||||||||

| C | SN | H | 660 | R | 46 | W | Z | T1 | / | 2P | 25 |

| 1. Industry code: No code (common use); C (special use on vessels); D (special use in electric power industry); S (special use in petrochemical industry); the "special use" means the product is specially designed and produced for an industry to meet the special requirements of the industry; 2. Mounting type: H (horizontal mounting); F (bracket-type mounting); S (vertical mounting); K (Immersion-type mounting); 3. Specification code: Refer to the performance parameter table for the details; 4. Spiral direction of power rotor: R (common use, with right-handed spiral direction of power rotor); L (left-h | |||||||||||

1. How to get our quotation in time, please answer following questions:

A.What liquid do you transfer? Oil, Water, Food or Corrosive Chemical liquid, with solid particle or not, and so on~

B. What's the flow or capcity (m3/h, L/m)?

C.What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

D. Contact us to get the quotation:

2. OEM: Ok

3. MOQ: 1set

4. Package: Standar export Plywood Case or Styrofoam with Carton

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Term of payment: 100% T/T, Aliexpress, L/C, Westunion

8. Why choose us: more than 20 years experiences manufacturer

Good quality with competitive pirce

ISO2000, CE certificate, CCS certificate

Professional after-sales service

content is empty!