Views: 61 Author: Site Editor Publish Time: 08-16-2020 Origin: Site

During the voyage, the gears of the main engine fuel delivery pump are stuck. It causes the main engine to slow down automatically due to low oil pressure, it wil seriously threatens the safety of the main engine and its supercharger.

After manual turning inspection, we can found the pump shaft was stuck. Then the pump casing was disassembled, we can found the gear meshing surface was seriously worn, and there were slight ablation marks. The gear was deformed and the bearing was seriously ablated.

Find out these phenomena, then how to locate and prevent the fault? Now I'd like to share this knowledge with you.

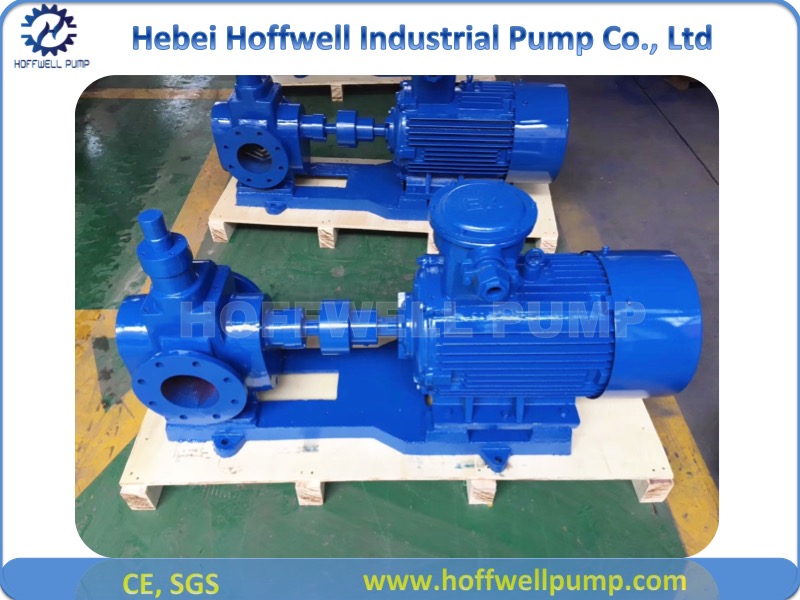

1. Working principle of 1 fuel transfer pump

Gear pump is a very common rotary positive displacement pump, its main working parts are meshing gears. Gear pump is to rely on working space increase and decrease to produce suction, discharge effect. With the rotation of the gear, a gear full of liquid turns around the suction chamber, along the inner wall of the pump to the discharge chamber. When they meshing again, the liquid pumped out by the gear and discharged continuously from the discharge port. Because the gear is always engaged, and the clearance between the pump cover and the gear surface is very small, the liquid with high pressure in the discharge chamber will not leak back to the suction chamber in large amount.

2 Analysis of causes

1) Content more solids in the fuel oil

As the ship often at foreign ports to fill the main engine fuel, the fuel quality is different, and there are many impurities, it will lead to frequent flushing of the fuel filter, and the solids can not be effectively discharged. The solids enter the fuel delivery pump through the filter, it makes the meshing gear friction by impurities, and then causes the gears wearing seriously and blocked.

2) Influence of assembly deviation and vibration deviation on gear pump

During the ship sailing on the sea, the delivery pump is working in a long time. Due to the vibration of pump seat caused by the operation of engine room equipment, There will be air in the filter cleaning system. If the air can not be discharged quickly, there will be "cavitation phenomenon", resulting in big noise, causing the pump vibrate, and the mechanical friction in the pump is serious or even stuck.

As the fuel transfer pump is related to the normal operation of the main engine, Hoffwell pump reminds you to do a good job in the scientific use and management of the equipment. In order to avoid the recurrence of such faults as far as possible, we should pay attention to the following points in daily management:

1. It is necessary to clean the filter regularly and check whether the filter is damaged. After cleaning the filter, the system should be deflated in time, and the suction pipeline should be checked regularly to avoid air inhalation.

2. It is not suitable to work beyond the rated pressure, otherwise it will overload the prime mover, increase the bearing load and deform the working parts.

3. Keep the fuel tank level at a certain height. When there is no oil or when the inlet and outlet valves are closed, do not working the pump. When the main engine is in standby state, do not working the oil pump in high-pressure operation.

Hoffwell pump reminds you, when there is a problem with the fuel delivery pump, you can check it according to the idea of this paper, solution maintenance, etc. to solve your urgent problem.