JSB

HOFFWELL

| Type: | |

|---|---|

| Material: | |

| Norminal Torque: | |

| Rotation Speed: | |

| HS Code: | |

| Origin: | |

| Availability: | |

| Quantity: | |

>>>Description

Grid Coupling is widely used in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools and other mechanical equipment and industry shaft transmission.

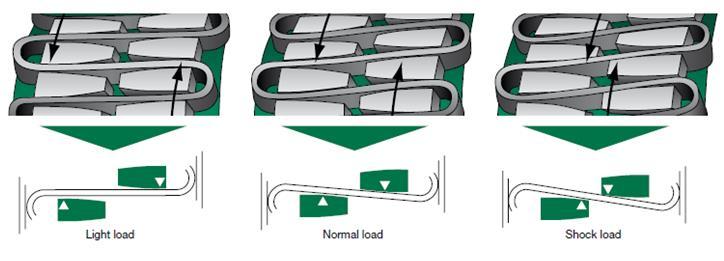

>>>Principle

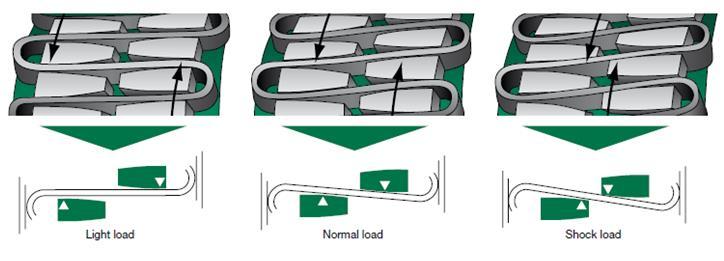

Positive protection against the damaging effects of shock loads, impact loads and vibration.

>>>Feature and Construction

1.The serpentine spring as the elastic element, the elastic strong at the same time, greatly improves the grid coupling torque, widely used in heavy machinery and general machinery.The serpentine spring special technology department, has long service life, allowing higher speed, has good ability to compensate in the axial, radial and angle.

2.High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is two times the rated torque, operation safety.

3.Simple structure, convenient assembly and disassembly, long service life.

4.Damping effect is good to avoid the resonance.

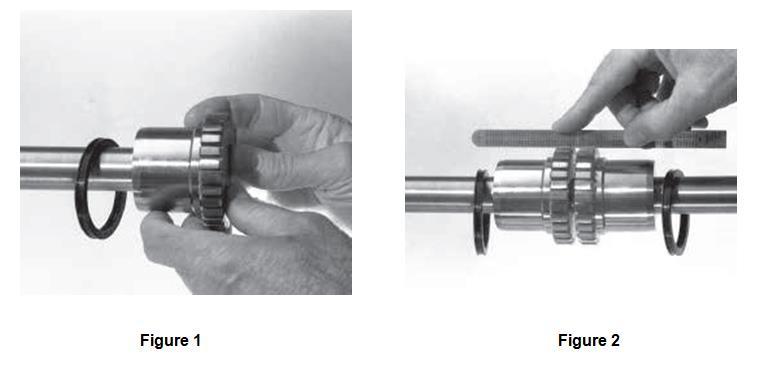

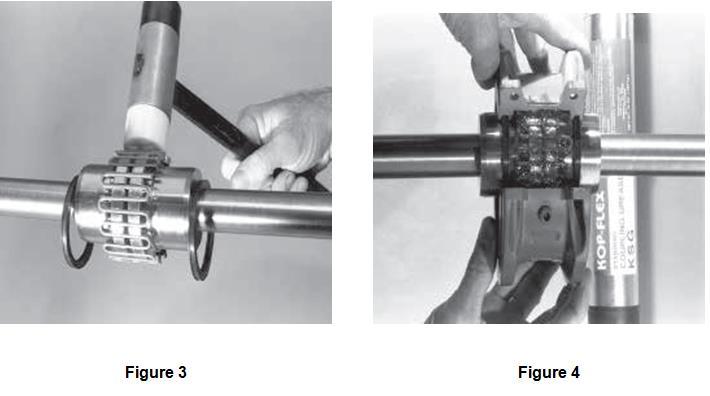

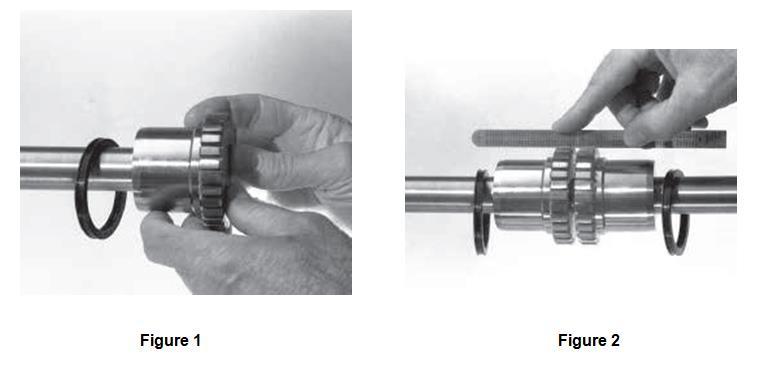

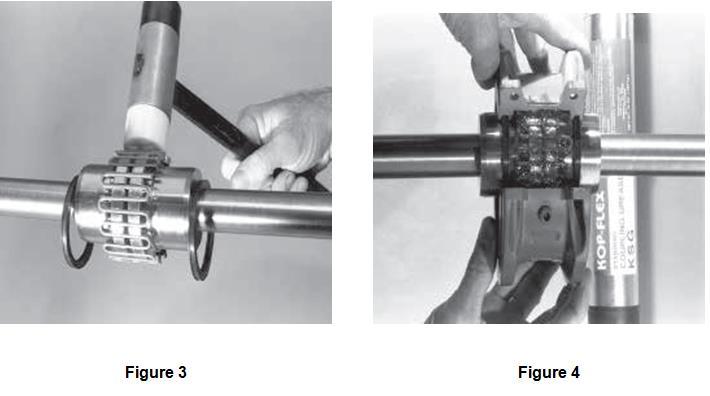

>>>Installing

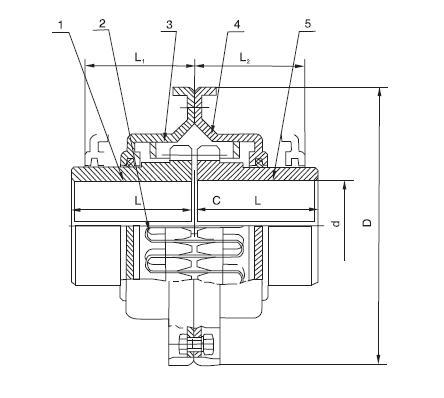

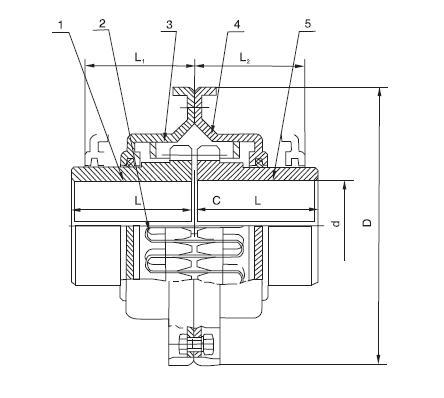

>>>Basic Parameter and Main Dimension

Type | Nominal torque Tn/ N·m | Max speed [n]/ r·min-1 | Bore diameter d | L | L1,L2 | D | C | Mass m /kg |

JSB1 | 45 | 6000 | 18、19 | 47 | 48 | 112 | 3 | 1.95 |

20、22、24 | ||||||||

25、28 | ||||||||

JSB2 | 140 | 22、24 | 122 | 2.59 | ||||

25、28 | ||||||||

30、32、35 | ||||||||

JSB3 | 224 | 25、28 | 50 | 51 | 130 | 3.36 | ||

30、32、35、38 | ||||||||

40、42 | ||||||||

JSB4 | 400 | 32、35、38 | 60 | 61 | 149 | 5.44 | ||

40、42、45、48、50 | ||||||||

JSB5 | 630 | 40、42、45、48、50、55、56 | 63 | 64 | 163 | 7.26 | ||

JSB6 | 900 | 5500 | 48、50、55、56 | 76 | 67 | 174 | 10.4 | |

60、63、65 | ||||||||

JSB7 | 1800 | 4750 | 55、56 | 89 | 89 | 200 | 17.7 | |

60、63、65、70、71、75 | ||||||||

80 | ||||||||

JSB8 | 3150 | 4000 | 65、70、71、75 | 98 | 96 | 233 | 25.4 | |

80、85、90、95 | ||||||||

JSB9 | 5600 | 3250 | 75 | 120 | 121 | 268 | 6 | 42.2 |

80、85、90、95 | ||||||||

100、110 | ||||||||

JSB10 | 8000 | 3000 | 80、85、90、95 | 127 | 124 | 287 | 54.4 | |

100、110、120 | ||||||||

JSB11 | 12500 | 2700 | 90、95 | 149 | 143 | 320 | 81.6 | |

100、110、120、125 | ||||||||

130、140 | ||||||||

JSB12 | 18000 | 2400 | 110、120、125 | 162 | 146 | 379 | 122 | |

130、140、150 | ||||||||

160、170 | ||||||||

JSB13 | 25000 | 2200 | 120、125 | 184 | 156 | 411 | 180 | |

130、140、150 | ||||||||

160、170、180 | ||||||||

190、200 | ||||||||

JSB14 | 35500 | 2000 | 140、150 | 183 | 204 | 476 | 230 | |

160、170、180 | ||||||||

190、200 | ||||||||

JSB15 | 50000 | 1750 | 160、170、180 | 216 | 216 | 533 | 321 | |

190、200、220 | ||||||||

240 | ||||||||

JSB16 | 63000 | 1600 | 180 | 226 | 584 | 448 | ||

190、200、220 | ||||||||

240、250、260 |

Note: When ordering JSB coupling, in addition to correctly marking the model and specification according to the specified marking method, it is also required to specify the length of the dimension between the two shaft ends.

>>>Description

Grid Coupling is widely used in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools and other mechanical equipment and industry shaft transmission.

>>>Principle

Positive protection against the damaging effects of shock loads, impact loads and vibration.

>>>Feature and Construction

1.The serpentine spring as the elastic element, the elastic strong at the same time, greatly improves the grid coupling torque, widely used in heavy machinery and general machinery.The serpentine spring special technology department, has long service life, allowing higher speed, has good ability to compensate in the axial, radial and angle.

2.High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is two times the rated torque, operation safety.

3.Simple structure, convenient assembly and disassembly, long service life.

4.Damping effect is good to avoid the resonance.

>>>Installing

>>>Basic Parameter and Main Dimension

Type | Nominal torque Tn/ N·m | Max speed [n]/ r·min-1 | Bore diameter d | L | L1,L2 | D | C | Mass m /kg |

JSB1 | 45 | 6000 | 18、19 | 47 | 48 | 112 | 3 | 1.95 |

20、22、24 | ||||||||

25、28 | ||||||||

JSB2 | 140 | 22、24 | 122 | 2.59 | ||||

25、28 | ||||||||

30、32、35 | ||||||||

JSB3 | 224 | 25、28 | 50 | 51 | 130 | 3.36 | ||

30、32、35、38 | ||||||||

40、42 | ||||||||

JSB4 | 400 | 32、35、38 | 60 | 61 | 149 | 5.44 | ||

40、42、45、48、50 | ||||||||

JSB5 | 630 | 40、42、45、48、50、55、56 | 63 | 64 | 163 | 7.26 | ||

JSB6 | 900 | 5500 | 48、50、55、56 | 76 | 67 | 174 | 10.4 | |

60、63、65 | ||||||||

JSB7 | 1800 | 4750 | 55、56 | 89 | 89 | 200 | 17.7 | |

60、63、65、70、71、75 | ||||||||

80 | ||||||||

JSB8 | 3150 | 4000 | 65、70、71、75 | 98 | 96 | 233 | 25.4 | |

80、85、90、95 | ||||||||

JSB9 | 5600 | 3250 | 75 | 120 | 121 | 268 | 6 | 42.2 |

80、85、90、95 | ||||||||

100、110 | ||||||||

JSB10 | 8000 | 3000 | 80、85、90、95 | 127 | 124 | 287 | 54.4 | |

100、110、120 | ||||||||

JSB11 | 12500 | 2700 | 90、95 | 149 | 143 | 320 | 81.6 | |

100、110、120、125 | ||||||||

130、140 | ||||||||

JSB12 | 18000 | 2400 | 110、120、125 | 162 | 146 | 379 | 122 | |

130、140、150 | ||||||||

160、170 | ||||||||

JSB13 | 25000 | 2200 | 120、125 | 184 | 156 | 411 | 180 | |

130、140、150 | ||||||||

160、170、180 | ||||||||

190、200 | ||||||||

JSB14 | 35500 | 2000 | 140、150 | 183 | 204 | 476 | 230 | |

160、170、180 | ||||||||

190、200 | ||||||||

JSB15 | 50000 | 1750 | 160、170、180 | 216 | 216 | 533 | 321 | |

190、200、220 | ||||||||

240 | ||||||||

JSB16 | 63000 | 1600 | 180 | 226 | 584 | 448 | ||

190、200、220 | ||||||||

240、250、260 |

Note: When ordering JSB coupling, in addition to correctly marking the model and specification according to the specified marking method, it is also required to specify the length of the dimension between the two shaft ends.

>>>Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001

>>>Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001

>>>FAQ

Q 1: Can you do OEM?

A: Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 2: How long is your delivery time?

A: Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 3: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 5: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 6: Do you have inspection procedures for coupling ?

A: 100% self-inspection before packing.

>>>FAQ

Q 1: Can you do OEM?

A: Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 2: How long is your delivery time?

A: Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 3: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 5: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 6: Do you have inspection procedures for coupling ?

A: 100% self-inspection before packing.

content is empty!